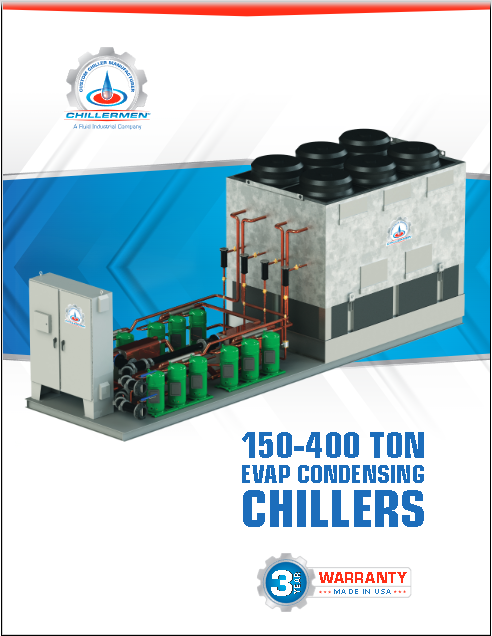

Evaprotive Condensing Chillers

1. NEMA 4 Control Panel

2. Flanged Supply/Return Connections

3. Factory Strainer

4. Brazed Plate Evaporator

5. Electronic Expansion Valves

6.Tandem or Trio Scroll Compressors

7. Dual Repalceable Core Filter Driers

8. Redundant Refrigeration Circuits

9. ECM Condenser Fans with Quiet BLades

10. Low Clog Spray System

11. Copper Condenser Coil

12. Stainless Steel Condenser Basin

40% More Efficient Than Air-Cooled

40% Smaller Footprint

100% Capacity at Any Ambient Temperature

EVCC SYSTEM BENEFITS

Plug and Play Operation

Serviceability and Reliability

Proprietary Controls Paradigm

Standard Features

Conformance and Regulations

Product Support

Custom Designed Systems

Manufacturing

For more information about these products, or to learn more about our other products and services, please contact Chillermen for more information.

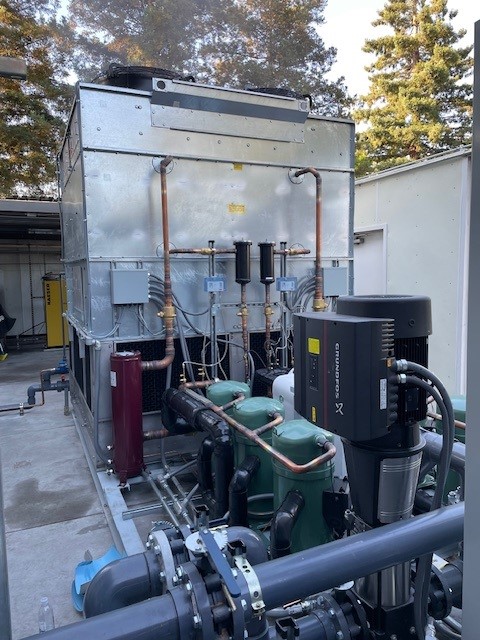

In The Field

Commercial Buiding

DEMAND RESPONSE, ICE STORAGE

Ask the Experts

Fill in the form below to ask.