PROCESS CHILLERS AND HEAT EXCHANGERS

Heat Exchangers

Widely used in industry both for cooling and heating large scale industrial processes, Heat Exchangers can be tailored to suit a process depending on the type of fluid, its phase, temperature, density, viscosity, pressures, chemical composition and various other thermodynamic properties. They are ideal for when in-house water is either too cold, too dirty, or doesn’t have enough pressure to adequately support your water cooled equipment.

While Heat Exchangers can be used in many industries, in waste water treatment, heat exchangers play a vital role in maintaining optimal temperatures within anaerobic digesters to promote the growth of microbes that remove pollutants.

In commercial aircraft heat exchangers are used to take heat from the engine’s oil system to heat cold fuel. This improves fuel efficiency, and reduces the possibility of water entrapped in the fuel freezing.

Other industries that use Heat Exchangers include: Refrigeration, Wine and beer making, Petroleum refining, and nuclear power.

The difference in-house water temperature must be at least 10° colder than the process water temperature or a heat exchanger will not work.

The Process Chiller pumps chilled water through process or laboratory equipment. Chillers are available as air cooled or water cooled. Both versions contain a compressor, condenser, evaporator and an expansion valve. An air-cooled chiller removes the heat by flowing air onto the condenser while a water-cooled chiller removes the heat by circulating cool water through the lines in the condenser.

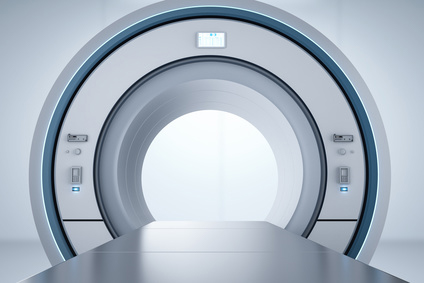

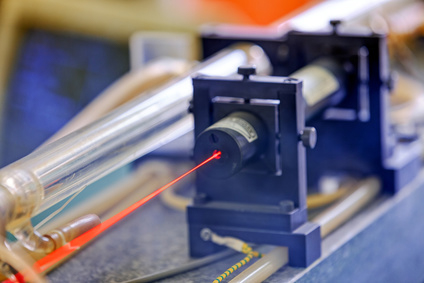

Industrial chillers are used for controlled cooling of products, mechanisms and factory machinery in a wide range of industries. They are often used in the plastic industries, injection and blow molding, metal working cutting oils, welding equipment, die-casting and machine tooling, chemical processing, pharmaceutical formulation, food and beverage processing, paper and cement processing, vacuum systems, X-ray diffraction, power supplies and power generation stations, analytical equipment, semiconductors, compressed air and gas cooling. They are also used to cool high-heat specialized items such as MRI machines and lasers.

Process Chillers

Benefits of Chillermen

Partnering with our clients during the conceptual design phase is crucial in making sure the final product meets our customers’ standards. That’s why our manufacturing process involves working closely with our clients every step of the way to final installation. We ensure that our equipment is compatible with a wide range of fluids, such as fluorinert, solvents, paints, and refrigerants. With our full-service, state-of-the-art facility in California, we are able to manage both small and mid-range production runs as well as 3-5 day burn-in testing services. Our post-installation services include follow-up maintenance, troubleshooting, international support, and 3-year warranties.

MANY INDUSTRIES NEED TEMPERATURE CONTROL EQUIPMENT LIKE CHILLERS & HEAT EXCHANGERS

Ask the Experts

Fill in the form below to ask.