OEM SERVICES

OEM EQUIPMENT CHILLERS & HEAT EXCHANGERS

We do what other chiller manufacturers don’t want to do!

Chillermen specializes in the design, engineering and manufacture of OEM heavy-duty industrial and commercial Chillers and heat exchangers. Our products are designed to exacting customer specifications and we test all units within a 3-7 day burn-in procedure to confirm our quality. Our heat exchangers eliminate condensing or evaporating, state-change, or vapor compression which is common with compressor-based chillers.

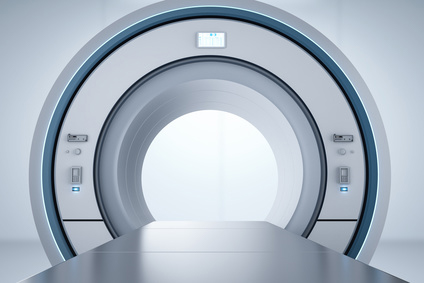

Chillers

Chillermen can handle full OEM production of process chillers.

At Chillermen, we manage both small and mid-range production runs, including prototypes. We also offer 3-5 day burn-in testing services. Working with a variety of liquids, ranging from fluorinert to refrigerants, we invite you to contact us today to learn more about our process chiller design and manufacturing services.

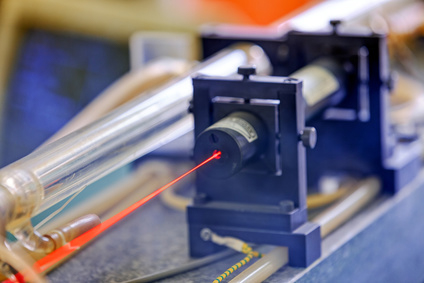

Heat Exchangers

Heat exchangers use house water and are usually limited to 60°F on the low end and 300°F on the high end, with a temperature accuracy as low as (+/-) .01°F.

Our typical OEM customer requires quantities of 10 to 500 units a year and this is well within our capabilities. We are capable of meeting the production needs for a variety of applications, from clean rooms to hazardous equipment, and can produce custom one-off units or manage full, mid-range production runs.

Contact our company today to learn more about our Chiller and heat exchanger design and manufacturing services.

Benefits of Chillermen

Partnering with our clients during the conceptual design phase is crucial in making sure the final product meets our customers’ standards. That’s why our manufacturing process involves working closely with our clients every step of the way to final installation. We ensure that our equipment is compatible with a wide range of fluids, such as fluorinert, solvents, paints, and refrigerants. With our full-service, state-of-the-art facility in California, we are able to manage both small and mid-range production runs as well as 3-5 day burn-in testing services. Our post-installation services include follow-up maintenance, troubleshooting, international support, and 3-year warranties.

We invite you to contact us today to learn more about our process chiller design and manufacturing services. Our team looks forward to working with you!

Ask the Experts

Fill in the form below to ask.